Machina Tondendi CNC Altae Qualitatis

1. Tota machinae structura uno tempore a centro Germanico SHW pentahedri processus tractatur.

4. Angulus tonsionis facile per programmationem aptari potest ne materiae ex sectione deformata sit.

5. Longitudo ictus trabis superioris automatice aptari potest ut celeris et accurata sectio brevium et parvarum materiarum efficiatur, quo efficientia laboris augeatur.

6. Systema CNC automatice intervallum laminarum secundum crassitudinem laminae et materiam variam accommodabit ut qualitatem sectionis meliorem reddat.

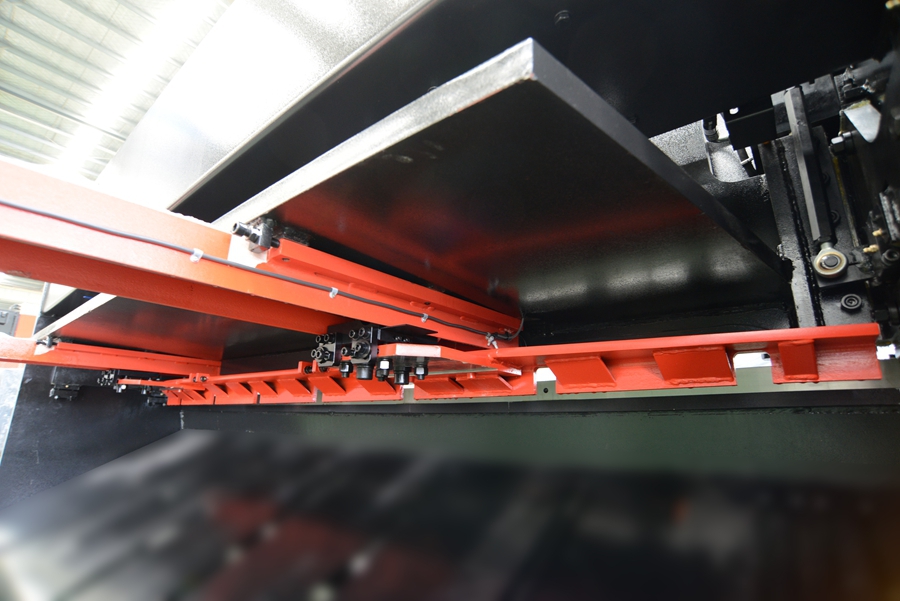

7. Lamina tonsura quadrilateralis ad vitam utilitatis laminae emendandam adhibetur, quae multo melior est quam forficis oscillatoriae.

8. Novum designum cinguli posterioris, structura stabilis, resistentiam detritionis, tolerantiam collisionis multum auget.

2. Systema CNC Delem DAC360 adoptat:

● accurate moderare mensuram posteriorem

● accurate ictum tonsionis moderare

● angulum tonsionis accurate moderare

● accurate spatium laminarum moderare

● Numerum operum accurate moderare.

3. Systema hydraulicum integratum BOSCH Germaniae adoptat:

● ad simplificandum ductum

●ad vitandam effusionem olei

● ad stabilitatem laboris emendandam

● ad ornandam machinae speciem

1. ad automatam moderationem machinae tonsoris cum plena functione anterioris alimentationis vel posterioris terminus adhibitum

2. ostentationem LCD altae definitionis, programmandi genus menu adoptat;

3. angulus tonsionis, hiatus laminae, computatio et moderatio automatica ictus tonsionis;

4. constructio modularis, definitio flexibilis vel extensio X1-X2 synchronizatae pascendi potestatis et auxiliaris Z axis potestatis;

5. programmationem positionis absolutae et positionis relativae adoptat;

6. inquisitio automatica puncti referentiae, et positio memoriae inactiva constitui potest;

7. singularis designatio rotae manualis ad machinam commode accommodandam;

8. Interfacies serialis RS232;

9. emissio signorum auxiliarium plurium ab usore definitorum;

10. programma autodiagnosis;

11. memoria interna 100 linearum programmatum;

12. LCD altae definitionis 4.7 unciarum;

13. functio numerandi programmata;

14. selectio unitatis magnitudinis inter systema metricum et systema Anglicum.

| Non. | Res | Quantitas | Nota |

| 1 | Fasciculi Machinales | Unum par | |

| 2 | Clavis hexagonalis | Unum par | |

| 3 | Pistola adiposa | Unus non. | |

| 4 | Clavus Terrae | Unum par | |

| 5 | Clavus Adaptans | Unum par | |

| 6 | Imperium Pedis | Unus non. |

1. Fons aeris: fac ut pressio gasis machinae suppedita plus quam 0.6 Mpa sit, fluxus gasis plus quam 0.3 m3/min sit.

2. Oleum hydraulicum: oleum hydraulicum importatum VG46# contra attritionem. Massa olei requisita infra statuitur:

| Modelus Machinae | Massa Olei (L) |

| Series VR6, VR8 | 230 |

| Series VRZ | DCXC |

| Series VR10 | 370 |

| VR13*3200 | 460 |

| VR13*6200 | DCCC |

3. Potentia: 380V, 50HZ, fluctuatio tensionis ±10%

4. Temperatura ambientis: 0°C - +40°C

5. Humiditas ambientis: humiditas relativa 20-80% RH (non condensans)

6. A fonte vibrationis fortis et perturbatione electromagnetica procul habe.

7. Parvus pulvis, nullus gas noxius aut corrosivus

8. Fundamentum secundum delineationem fundamenti para.

9. Personas relativas cum certa educatione ad pactum diuturnum ut operator machinae elige.

Machina Tondendi CNC; tonsura ghillotinae hydraulica; machina tondendi; tonsura CNC

2500

| Descriptio | Unitas | 6*2500 | |

| Crassitudo Tondendi (mm) | Chalybs mollis 450Mpa | mm | 0.5-6 |

| Chalybs Inoxidabilis 600Mpa | 0.5-4 | ||

| Aluminium 300Mpa | 0.5-8 | ||

| Longitudo Tondendi | mm | 2500 | |

| Angulus Tondendi | ° | 0.5°~2° | |

| Retro- mensura | Ictus mm | mm | 5~1000 |

| Celeritas mm/s | mm/s | ≤250 | |

| Accuratio mm | mm | ±0.1 | |

| Potentia Motoris Servomotoris (KW) | KW | 1 | |

| Tempora Ictus | hpm | XXV-XXXVI | |

| Capacitas Cylindri (L) | L | 230 | |

| Numerus prehensionis | non. | 12 | |

| Potentia Motoris Primarii (KW) | KW | 11 | |

| Systema CNC | Systema CNC Hollandicum Delem DAC360 angulum tonsionis, intervallum laminarum, et cursum tonsionis moderans | ||

| Numerus et longitudo brachii sustentatoris (mm) | mm | 3*1400 | |

| Dimensio Adumbrata | Longitudo (mm) | mm | 3110 |

| Latitudo (mm) | mm | tria milia | |

| Altitudo (mm) | mm | MDCCV | |

3000/3200

| Descriptio | Unitas | Sex * tria milia | Octo*3000 | 10*3000 | 13*3200 | 16*3200 | ||||

| Crassitudo Tondendi (mm) | Chalybs mollis 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||

| Chalybs Inoxidabilis 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||

| Aluminium 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||

| Longitudo Tondendi | mm | 3070 | 3070 | 3070 | 3200 | 3200 | ||||

| Angulus Tondendi | ° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | 0.5°-2° | ||||

| Retro- mensura | Ictus mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||

| Celeritas mm/s | mm/s | ≤250 | ≤250 | ≤250 | ducenti | ducenti | ||||

| Accuratio mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||

| Potentia Motoris Servomotoris (KW) | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||

| Tempora Ictus | hpm | XXII-XXXV | XVI-XXXIV | XV-XXXII | 10-15 | 9-16 | ||||

| Capacitas Cylindri (L) | L | 230 | 230 | 370 | 460 | 460 | ||||

| Numerus prehensionis | non. | 14 | 14 | 14 | 15 | 15 | ||||

| Potentia Motoris Primarii (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||

| Systema CNC | Systema CNC Hollandicum Delem DAC360 angulum tonsionis, intervallum laminarum, et cursum tonsionis moderans | |||||||||

| Numerus et longitudo brachii sustentatoris (mm) | mm | 3*1400 | 3*1400 | 3*1400 | 3*1000 | 3*1000 | ||||

| Dimensio Adumbrata | Longitudo (mm) | mm | 3610 | 3640 | 3720 | 4075 | 4300 | |||

| Latitudo (mm) | mm | tria milia | tria milia | 3040 | 2752 | tria milia | ||||

| Altitudo (mm) | mm | MDCCV | MDCCLV | MDCCCLXXX | 2432 | 2850 | ||||

Quadringenta milia

| Descriptio | Unitas | 6*4000 | Octo*4000 | 10*4000 | 13*4000 | 16*4000 | ||||||

| Crassitudo Tondendi (mm) | Chalybs mollis 450Mpa | mm | 0.5-6 | 0.8-8 | 0.8-10 | 1-13 | 1-16 | |||||

| Chalybs Inoxidabilis 600Mpa | 0.5-4 | 0.8-5 | 0.8-7 | 1-8 | 1-10 | |||||||

| Aluminium 300Mpa | 0.5-8 | 0.8-10 | 0.8-12 | 1-18 | 1-20 | |||||||

| Longitudo Tondendi | mm | 4070 | 4070 | 4070 | Quadringenta milia | Quadringenta milia | ||||||

| Angulus Tondendi | ° | 0.5°~2° | 0.5°~2° | 0.5°~2° | 0.5°~2.5° | 0.5°~2.5° | ||||||

| Retro- mensura | Ictus mm | mm | 5~1000 | 5~1000 | 5~1000 | 5-1000 | 5-1000 | |||||

| Celeritas mm/s | mm/s | ≤250 | ≤250 | ≤250 | ≤200 | ≤200 | ||||||

| Accuratio mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||||

| Potentia Motoris Servomotoris (KW) | KW | 1 | 1 | 1 | 1.0 | 1.0 | ||||||

| Tempora Ictus | hpm | XVI~XXXIV | XIV~XXXII | XII~XXXII | 10-15 | VIII-XV | ||||||

| Capacitas Cylindri (L) | L | 230 | 230 | 370 | 460 | 460 | ||||||

| Numerus prehensionis | non. | 18 | 18 | 18 | 19 | 19 | ||||||

| Potentia Motoris Primarii (KW) | KW | 11 | 15 | 22 | 30 | 37 | ||||||

| Systema CNC | Systema CNC Hollandicum Delem DAC360 angulum tonsionis, intervallum laminarum, et cursum tonsionis moderans | |||||||||||

| Numerus et longitudo brachii sustentatoris (mm) | mm | 4*1400 | 4*1400 | 4*1400 | 4*1000 | 4*1000 | ||||||

| Dimensio Adumbrata | Longitudo (mm) | mm | 4610 | 4640 | 4720 | 4970 | 5300 | |||||

| Latitudo (mm) | mm | tria milia | tria milia | 3040 | 2760 | tria milia | ||||||

| Altitudo (mm) | mm | MDCCV | MDCCV | MDCCCLXXX | 2562 | 2850 | ||||||

6000/6200

| Descriptio | Unitas | 6*6000 | Octo*6000 | 13*6200 | 16*6000 | 16*6200 | |||

| Crassitudo Tondendi (mm) | Chalybs mollis 450Mpa | mm | 0.5~6 | 0.8~8 | 1-13 | 1-16 | 1-16 | ||

| Chalybs Inoxidabilis 600Mpa | 0.5~4 | 0.8~5 | 1-8 | 1-10 | 1-10 | ||||

| Aluminium 300Mpa | 0.5~8 | 0.8~10 | 1-18 | 1-20 | 1-20 | ||||

| Longitudo Tondendi | mm | 6140 | 6140 | 6200 | Sex milia | 6200 | |||

| Angulus Tondendi | ° | 0.5˚-2˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2.5˚ | 0.5˚-2˚ | |||

| Retro- mensura | Ictus mm | mm | 5-1000 | 5-1000 | 5-1000 | 5-1000 | 5-1000 | ||

| Celeritas mm/s | mm/s | ducenti | ducenti | ducenti | ducenti | ducenti | |||

| Accuratio mm | mm | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |||

| Potentia Motoris Servomotoris (KW) | KW | 1.0 | 1.0 | 1.0 | 1.5 | 2.0 | |||

| Tempora Ictus | hpm | XII~XX | XII~XX | VI-X | 5-9 | 5-9 | |||

| Capacitas Cylindri (L) | L | DCXC | DCXC | DCCC | DCCC | DCCC | |||

| Numerus prehensionis | non. | 29 | 29 | 27 | 27 | 27 | |||

| Potentia Motoris Primarii (KW) | KW | 11 | 15 | 30 | 37 | 37 | |||

| Systema CNC | Systema CNC Hollandicum Delem DAC360 angulum tonsionis, intervallum laminarum, et cursum tonsionis moderans | ||||||||

| Numerus et longitudo brachii sustentatoris (mm) | mm | 6*1000 | 6*1000 | 6*1000 | 6*1000 | 6*1000 | |||

| Dimensio Adumbrata | Longitudo (mm) | mm | 7055 | 7115 | 7220 | 7300 | 7500 | ||

| Latitudo (mm) | mm | 2686 | 2690 | 2945 | tria milia | tria milia | |||

| Altitudo (mm) | mm | 2495 | 2680 | 2850 | 2850 | 2850 | |||

Series VR (Z):

| Non. | Nomen | Modellum | Nota |

| 1 | Systema CNC | Systema CNC DAC360 | Hollandia Delem |

| 2 | Motor Servo | EMJ-10APB22 | Estun |

| 3 | Servomotor | RONET-E-10A-AMA | Estun |

| 4 | Systema Hydraulicum | Valvae electro-servohydraulicae | Bosch-Rexroth Germania |

| valvula pressionis proportionalis | |||

| b. valvula cartusaria | |||

| c. valvula selectoria electromagnetica | |||

| d. valvula pressionis superimposita | |||

| e. valvula unidirectionalis moderationis hydraulicae | |||

| valvula suffocatoria | |||

| e. valvula unidirectionalis etc. | |||

| 5 | Ductus linearis | HSR25A-1240L | THK vel PMI |

| 6 | Cochlea globularis | 25/20-1400mm | THK vel PMI |

| 7 | Antlia olei | IPH-5B-50-11or PGH4-3X/050-E11VU2 | Antlia NACHI Iaponiae vel Rexroth Germaniae |

| 8 | Completa series anulorum obturantium in cylindro olei | PARKER USA | PARKER USA |

| 9 | Completus apparatus fistularum altae pressionis | 1.F372C91C161608-1200mm | Iunctura tuborum PARKER,EO-2 in Civitatibus Foederatis Americae vel iunctura tuborum VOSS in Germania |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4. F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Aut F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF cetera. | |||

| 10 | Copulatio | R38 25.385/42 cetera. | Germania KTR |

| 11 | Contactor AC | LC1-D38B7C, LC1-D25B7Cet cetera. | Schneider |

| 12 | Commutator proximitatis | TP-SM5P2 et cetera. | TENDE |

| 13 | Ductus terminalis | TB2.5B TB16ICH cetera. | Phoenix |

| 14 | Globulus | XB2-BVB3LC cetera. | Schneider |

| 15 | Pictura | KAILEDI |

Series VR (Z):

| Non. | Nomen | Modellum | Nota |

| 1 | Systema CNC | Systema CNC DAC360 | Hollandia Delem |

| 2 | Motor Servo | EMJ-10APB22 | Estun |

| 3 | Servomotor | RONET-E-10A-AMA | Estun |

| 4 | Systema Hydraulicum | Valvae electro-servohydraulicae | Bosch-Rexroth Germania |

| valvula pressionis proportionalis | |||

| b. valvula cartusaria | |||

| c. valvula selectoria electromagnetica | |||

| d. valvula pressionis superimposita | |||

| e. valvula unidirectionalis moderationis hydraulicae | |||

| valvula suffocatoria | |||

| e. valvula unidirectionalis etc. | |||

| 5 | Ductus linearis | HSR25A-1240L | THK vel PMI |

| 6 | Cochlea globularis | 25/20-1400mm | THK vel PMI |

| 7 | Antlia olei | IPH-5B-50-11or PGH4-3X/050-E11VU2 | Antlia NACHI Iaponiae vel Rexroth Germaniae |

| 8 | Completa series anulorum obturantium in cylindro olei | PARKER USA | PARKER USA |

| 9 | Completus apparatus fistularum altae pressionis | 1.F372C91C161608-1200mm | Iunctura tuborum PARKER,EO-2 in Civitatibus Foederatis Americae vel iunctura tuborum VOSS in Germania |

| 2.F372C91C161608-1950mm (2950mm) | |||

| 3.F381CACF151508-1480mm | |||

| 4. F381CFCF151508-2140mm (3140mm) | |||

| 5.F451TCACF121206-1600mm | |||

| 6.F3720C19201612-1300mm Aut F3720C1C202512-1300mm | |||

| 7.GE12ZLREDCF | |||

| 8.GE16SREDOMDCF | |||

| 9.GE42ZLREDCF cetera. | |||

| 10 | Copulatio | R38 25.385/42 cetera. | Germania KTR |

| 11 | Contactor AC | LC1-D38B7C, LC1-D25B7Cet cetera. | Schneider |

| 12 | Commutator proximitatis | TP-SM5P2 et cetera. | TENDE |

| 13 | Ductus terminalis | TB2.5B TB16ICH cetera. | Phoenix |

| 14 | Globulus | XB2-BVB3LC cetera. | Schneider |

| 15 | Pictura | KAILEDI |