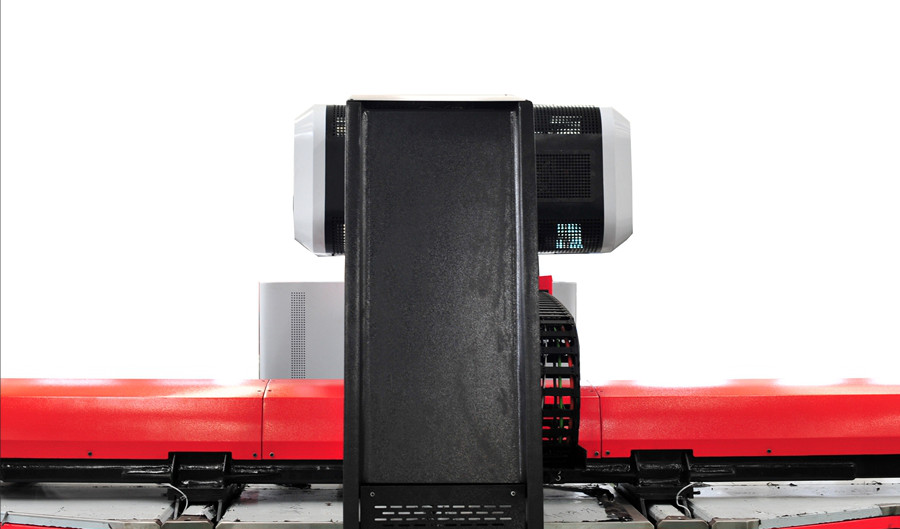

Machina Punctatoria Turris CNC Altae Qualitatis

1. Systema uno servomotore actum, servomotorem magnum momentum directe actum et unitatem impulsivam cum magna capacitate onerandi adhibet, ut consumptionem energiae humilem, efficientiam transmissionis magnam, functionem certam et sustentationem commodam efficiat.

(1) Celeritas et ictus adaptabiles

a. Ictus perforationis secundum crassitudinem laminae automatice eligi potest, quo efficientia operis augeatur.

b. Celeritas perforationis in unoquoque puncto cuiusque stationis singularis adaptari potest.

c. Machina celeritatem magnam et celeritatem minorem in cursu vacuo et in vero punctu assequi potest; hoc modo, qualitas punctionis efficaciter augeri potest, et nullus vere strepitus est in punctu.

(2). Systema praesidio contra nimium currentem et mechanica praesidii contra nimium currentem praeditum est.

(3). Vis perforationis secundum crassitudinem laminae et celeritatem cursus aris automatice aptari potest ut qualitas perforationis ad summum gradum perveniat.

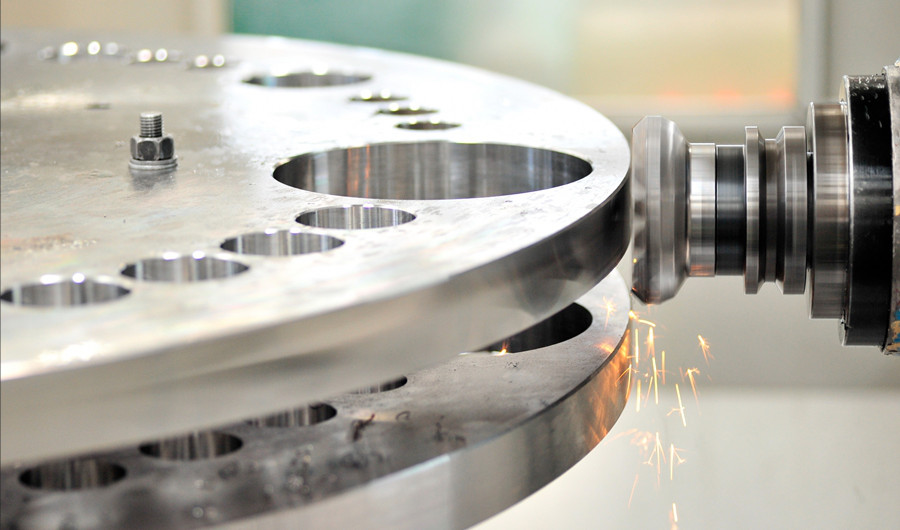

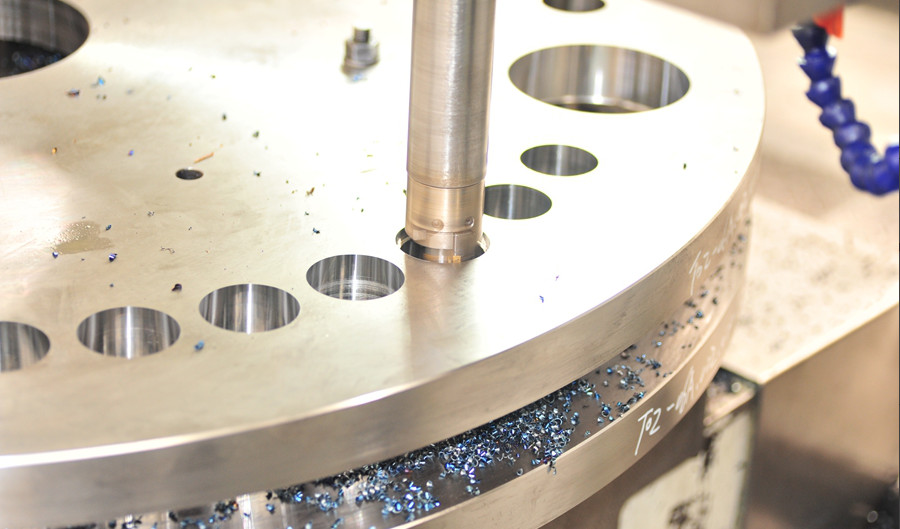

2. Turris cum bushing in paribus processus est

Turris instrumento speciali tractatur ut coaxialitas turris superioris et inferioris confirmetur et vita utilis instrumentorum extendantur; turris induta structuram turris simplificat ut vita utilis extendantur; instrumenta longa adhiberi possunt ad accuratiam gubernationis augendam et vitam utilis instrumentorum (pro lamina crassa) extendendam.

3. Partes pneumaticae, lubricantes et electricae importatae firmitatem totius machinae praestant.

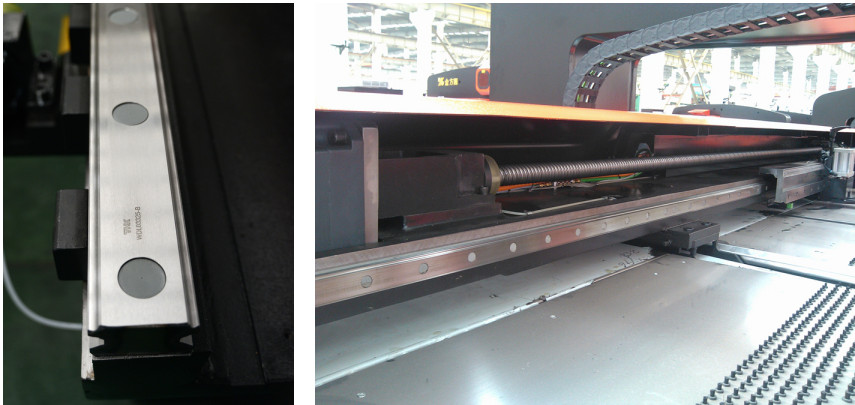

4. Magna dux plumbea et cochlea sphaerica ex Iaponia vel Germania praestant cibum praeclare et accurate.

5. Mensa laboris mixta penicillo duro et globo sonitum et vibrationem dum currit minuit et superficiem laminae etiam protegit.

6. Structura ferrea, typi O, bis vibrata est, tensio omnino deleta. Structura a centro Germanico pentahedrico bifronti SHW simul tractatur, nec opus est secunda positione uti.

7. Fibula fluitans magna vi premente stabilem alimentationem praestat; currus integratus bonam rigiditatem et commodum motum fibulae praestat.

8. Systema munitum est functione automaticae tutelae contra fibulam, ne instrumenta et fibula detrimentum patiantur, ita ut continuus programmatis cursus fiat.

9. Index automaticus rotam vermiculam et mechanismum vermiculatum summae accuratiae adhibet, indicationem summae praecisionis praestans. Diameter maximus instrumenti 88.9mm attingere potest et index automaticus ad 4 numeros extendi potest.

10. Structura trabis integrata ut currum et trabem in unam partem convertat, rigiditatem augens et accuratam positionem efficiens. Machina multo stabilius currere potest durante celeritate alimentationis et finem imponit deflexionis axium X et Y.

11. Axis X: servomotore utitur ad globulos summae praecisionis agendos, currus autem rigiditate magna et levitate praeditus est. Axis Y: servomotor directe craticulam alimentariam agit, quae cum ductore machinae coniuncta est; trabs divisa cum craticula alimentaria fixa est, et vis agens per craticulam alimentariam et ductorem ad structuram machinae et solum transmittetur, ut vibratio propria trabis minuatur. Haec structura bonae rigiditatis, levitatis, gravitatis humilis, bonae responsionis dynamicae in toto systemate alimentario, cursu stabili et bona praecisione praedita est.

12. Systema lubricationis centrale adhibitum est ad adipem lubricantem directe ad punctum lubricationis relativum mittendum, frictionem singulorum parium operantium minuens et vitam utilem augens.

13. Interruptor contra deformationem laminae et interruptor contra exutionem laminae adoptatur.

| Non. | Nomen | Quantitas | Nota |

| 1 | Index Sarcinarum | 1 par | |

| 2 | Certificatum Qualitatis | 1 par | |

| 3 | Manual Operationis Mechanicae | 1 par | |

| 4 | Manuale Operationis Electricae | 1 par | |

| 5 | Delineatio fundamenti | 1 par | |

| 6 | Delineatio Principalis Electrica | 1 par | |

| 7 | Documenta Systematis Programmatum Auto-Programmatici | 1 par | |

| 8 | Delineatio Principalis Electrica DBN | 1 par | |

| 9 | Manuale instrumentorum | 1 par | |

| 10 | Manuale systematis CNC | 1 par | |

| 11 | Instrumentorum Delineatio | 1 par |

| Non. | Nomen | Gauge | Quantitas |

| 1 | Clavis bicipitis | 5.5×7-22×24 | 1 par |

| 2 | Clavis mobilis | ducenti | 1 numerus. |

| 3 | Clavis capitis socketi | S1.5-S10 | 1 par |

| 4 | Cochlea Crucis | 100×6 | 1 numerus. |

| 5 | Pistola adiposa | HS87-4Q | 1 numerus. |

| 6 | Pistola Compressoris Antliae Lubricationis Adipis | SJD-50Z | 1 numerus. |

| 7 | Sclopetum altae pressionis | 1 par | |

| 8 | Globulus formae T | M14×1.5 | 1 numerus. |

| 9 | Commutator accessus | M12 PNP SN=2 apertum | 1 par |

| 10 | Commutator accessus | M12 PNP SN=2 claudere | 1 numerus. |

| 11 | Clavis | T09-02,500,000-38 | 1 numerus. |

| 12 | Clavis ad commutatorem cylindri gasii | 1 par | |

| 13 | Fistula mollis | Ø 12 | 1 numerus. |

| 14 | Acus tubi mollis | KQ2H12-03AS | 1 par |

| 15 | Partes fundamentorum | 1 numerus. |

| Non. | Nomen | Gauge | Quantitas | Nota |

| 1 | Tabula dentata fibulae | Tres numeri. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Tabula portatilis prehensa | Sex numeri. | T02-20A.000.000-09C Aut T02-20A.000.000-23A | ||

| 2 | Cochlea parva in fibula vernali | M4x10 | Viginti numeri. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | Cochlea in fibula Cochlea interna | M8 × 1 × 20 | Numerus XX. | |

| 4 | Lamina tonsura | 30T | Duo numeri. | T09-16.310,000-0.1.2 |

| 5 | Cochlea interna | M8 × 1 × 20 | quattuor numeri. |

Systema CNC FANUC est systema CNC specializatum, a FANUC Iaponia elaboratum praecipue ad huius generis machinae proprietates implendas, firmitatem machinae magnopere augendo.

I. Proprietates Systematis

1. Functio graphica et pungendi;

2. Commodum programma universale codicis G ad facilem operationem;

3. Portus universalis RS232 ad commode cum computatro communicandum;

4. Motor servo et systema servo plene digitale provectum;

Ostentus coloratus LCD 5.10.4″;

6. Semi-iterationis feedback codificatoris impulsuum;

7. Memoria EMS: 256K;

8. Programma in agro, programma in officio;

9. Sinica et Anglica ostentatio;

10. Functio simulationis graphicae;

11. Una charta PCMCIA magnae capacitatis ad parametros systematis, delineationem scalarum et programmata tractanda servanda, et ad processum interretialem programmatis tractandi magnae capacitatis efficiendum;

12. Incrementum in minima unitate, detectio positionis et imperium servo ad celeritatem magnam et operationem summam accuratam efficiendam;

13. Globulus operationis in tabula secundum veram necessitatem definiri potest;

14. Funes datorum embrayage celerissimi cum parvo nexu funium;

15. Alta integratio, programmatura specializata. Brevis tempus ad incipiendum, notitia non peribit si subito copia electrica deficit;

16. Repositio programmatis quadringentorum.

1. Axes lineares: axes X, axes Y, axes rotantes: axes T, axes C, axis punctionis: axis Z;

2. Alarma pro errore electrico ut ictu excessivo.

3. Munus autodiagnosis.

4. Functio limitis mollis.

5. Universalis G codex pro programmate;

6. Functio compensationis instrumentorum;

7. Functio compensationis distantiae cochlearum;

8. Functio compensationis hiatus inversi;

9. Functio deflectionis coordinatarum;

10. Functio repositionis;

11. Functio AUTO, MANUAL, modus JOG;

12. Munus tutelae fibulae;

13. Munus serae registri interni;

14. Functio programmatis parametri;

15. Functio subprogrammatis;

16. Functio celeris positionis et clausurae pugni;

18. Functio codicis M;

19. Programma absolutum et incrementale;

20. Saltus conditionans, deconditionans.

Introductio programmatis programmandi

CNCKAD a societate METALIX adhibemus. Hoc programma completum apparatum programmatum CAD/CAM automatici programmandi a consilio ad productionem praebet. Bibliotheca formarum administrata, selectio automatica modi, optimizatio itineris, aliaeque functiones, per delineationes CAD automatice generari possunt. Programmationem partis singularis, nidificationem automaticam, et fasciculum completum consequi potes.

Functio Delineationis CNCKAD graphica potens, facilis et intuitiva ad usum, praeter functionem delineationis consuetam secundum proprietates laminae metallicae, methodos delineationis speciales addit, ut incisio, rotunditas, triangulus, angulus rectus et formae lineae extremae, subictio, recensio et correctio automatica, sectio vel impressio, characteres Sinicos in fasciculos DXF/IGES/CADL/DWG, etc.

b) Munus Percussionis

Praebet perforatione automatica, forma speciali, indice automatico, relocatione automatica, sectione marginis, et aliis functionibus.

c) Munus Tondendi

Automatice lineamentorum inspicitur et parametros generis materiae, crassitudinis, sectionis singularis, sectionis, et relocationis tonsionis, aliarumque functionum corrigitur, necnon processus automaticus tonsionis laminae implementationis.

d) Postprocessus

Processus automaticus vel interactivus omnes processus comprehendit: impressionem, laserem, plasmam, ignem, aquae sectionem et fresaturam.

Processus posterior provectus omne genus codicis NC efficacis producere potest, subroutines et macroprogrammata sustinere, ut optimizationem viae instrumenti et minimam rotationem formae, injectionem adiuvare, functiones machinae suctionis vacui ut materiam et ratem labentium fragmentorum.

Transferre programma ad aliam machinam paucis tantum cliccis muribus requirit. Haec a methodo post-processus CNCKAD derivantur, eliminando superfluas fasciculas computatrales, quae operationem magis optimizant.

e) Simulatio graphica CNC

Programma quamlibet simulationem graphicam programmatis CNC, incluso codice CNC manu scripto, sustinet; processus edendi etiam valde simplex est; programma errores automatice inspicere potest, ut errores parametrorum amissorum in fibula et distantia, etc.

f) Transformatio a NC ad Delineationem

Sive manu scriptus sive alius codex NC, facile in graphica partium converti potest.

g) Relatio de Data

Relationem datorum imprimere potest, omnes informationes sicut numerus partium, processus informationum sicut tempus, formae dispositio, etc. comprehendens.

h) Transmissio DNC

Interfaciem Fenestram moduli transmissionis adoptans, ut transmissio inter PC et apparatum machinae facillima sit.

1) Omnes typos hodiernos perforationis CNC turris, machinae secandi laseris, machinae secandi plasmatis, machinae secandi flammae aliarumque machinarum instrumentorum sustinemus.

2) Totum processum operationis instrumentorum CNC sustine, inter quae delineatio, processus automaticus vel interactivus, processus posterior, programmata simulationis CNC, sectio manualis et automatica, receptio et immissio fasciculorum NC, et cetera.

3) Imagines Autocad, SolidEdge, SolidWork, CadKey etc. directe inserere potest, inter quas omnia documenta graphica programmatibus CAD claris generata.

4) Programma varia instrumenta moderationis numericae sustinet, partes NC ponere potest ut varia documenta instrumentorum generet, pro multis instrumentis simul dum tractatur.

Repositionatio Automatica

Cum magnitudo laminae maior est quam certum limitem, machina sponte denuo se collocat, deinde instructiones collocandi sponte generat; si usus requisita specialia habet, suas proprias instructiones collocandi mutare vel delere potest.

Vitatio automatica prehensionis

Instructiones per positionem automaticam generatae, quae fibulam zonam mortuam vitare possunt, iacturam minuere; sive lamina pars est sive plures partes laminae ferreae, operatio vitandae fibulae perfici potest.

Processus materiae in taenia

Ut deformatio materiae in processu impressionis minuatur, ars tractationis materiae in taenia adhiberi potest, et instrumentum secans in fronte vel tergo instructionis rami adhiberi potest.

Ars putationis

Cum functione perforationis marginis communis coniuncta, perforatio automatica quae materiam fractam circa marginem perforare potest.

Singula tranquillitas sponte movetur

Cum fibula mobili, machina a programmate generari potest fibulam automatice movens per instructiones NC.

Minima rotatio matricis

Optio rotationis minimae matricis detritionem stationis indicationis automaticae minuere et efficientiam productionis augere potest.

Functio Plurium Typorum Perforationis

Functio perforationis triangularis, perforationis obliquae, perforationis arcualis, et aliarum methodorum perforationis singularium et efficacium.

Functio Fortis Auto-Percussionis

Inter proprietates Perforationis Automaticae sunt nexus micro automaticus, selectio intellegens formae, et copia detectionis alarmis aliarumque functionum.

I) Functio secandi automatica

METALIX CNCKAD continet componentem AutoNest, quod est series programmatum ad nidificationem automaticam optimizationis laminarum verarum, quae omnem optimizationem laminae metallicae per methodos technicas efficere potest.

1. Copia aeris: pressio operandi aestimata plus quam 0.6mPa esse debet, fluxus aeris: plus quam 0.3m3/min

2. Potentia: 380V, 50HZ, fluctuatio potentiae: ±5%, potentia electrica 30T est 45KVA, diameter funis dynamici est 25mm², interruttor est 100A. Si fons potentiae non stabilis est, stabilisator requiritur; si effusio electrica est, praesidium requiritur.

3. Oleum hydraulicum: (SHELL) Tonna T220, vel aliud oleum ad lubricationem ductorum et ferriviarum.

Oleum lubricans: unguentum pressionis extremae 00#-0# (GB7323-94), consilium: infra 20°C unguentum pressionis extremae 00# utere, supra 21°C unguentum pressionis extremae 0# utere.

| Nota | Nomen | Observationes | Temperatura |

| Testa | EPO | 0# Unguentum pressionis extremae | 21°C supra |

| Testa | GL00 | 00# Unguentum pressionis extremae | 20°C infra |

3. Temperatura ambientis: 0°C - +40°C

4. Humiditas ambientis: humiditas relativa 20-80% RH (sine condensatione)

5. A vibratione valida vel impedimento electromagnetismi abstine.

6. Ambitus cum parvo pulvere, nullo gas venenato

7. Fundamentum secundum delineationem fundamenti para.

8. Usor technicum vel machinatorem ad institutionem eligere debet, cuius educatio saltem ex schola secundaria technica graduata sit, et eam in longum tempus disponere.

11. Fundamentum secundum delineationem praeparandum est.

12. Clavis fixa 65mm aperturae, virga sustentans postcombustoris, ad planitiem fundamentorum adaptandam.

13. Plus quam quinque litrae benzinae purae, panni nonnulli, sclopetum, oleum lubricans, circiter unum litrum ad machinas et formas fricandas.

14 cum una virga aenea Ф10*300 et una Ф16*300 ad formam instituendam. Trabs longa (fuselagium et trabs separatim involucris continentur, sed etiam ad unitates missas praeparandas)

15 indicator rotatorius (in ambitu 0-10mm), ad perpendicularitatem axium X et Y investigandam adhibitus.

16 Cum apparatus ad officinam pervenerit, gruem 20T vel ad apparatum elevandum para.

17. Si axis V motore refrigeratorio aquae instructus est, mediana refrigerationis conexa praeparanda est, volumen 38L est.

Aliae res non tractatae ulteriore interpretatione et coordinatione indigent.

Machina Perforatoria CNC Turris; perforatorium turris; prelum perforatorium turris; perforatio CNC; machina perforatoria turris; prelum perforatorium CNC; prelum perforatorium turris CNC; perforatorium turris CNC; machina perforatoria CNC; perforatorium turris venale; machina preli perforatorii turris; machina preli perforatorii CNC, machina perforatoria CNC venalis; machina preli perforatorii turris CNC; machina perforatoria et flectens CNC; prelum perforatorium turris cum imperio numerico; prelum perforatorium turris cum impulsu servo; prelum perforatorium turris venale

| Non. | Specificatio | Unitas | Modelus Machinae | ||

| MT300E | |||||

| 1 | Vis Ictus Maxima | kN | trecenti | ||

| 2 | Typus Impulsionis Praecipuus | / | Uno motore impulsus | ||

| 3 | Systema CNC | / | Systema CNC FANUC | ||

| 4 | Maxima Magnitudo Chartae Processandae | mm | 1250*5000 (cum una repositione) | 1500*5000 (cum una repositione) | |

| 5 | Numerus Fibulae | non. | 3 | ||

| 6 | Crassitudo Maxima Laminae Processoriae | mm | 3.2/6.35 | ||

| 7 | Diameter Puncti Maximus per Tempus | mm | Φ88.9 | ||

| 8 | Ictus Percussoris Principalis | mm | 32 | ||

| 9 | Ictus Maximus ad Passum 1mm | hpm | DCCLXXX | ||

| 10 | Ictus Maximus Calidus ad Passum 25mm | hpm | quadringenti | ||

| 11 | Maxima Celeritas Mordendi | hpm | MDCCC | ||

| 12 | Numerus Cylindri Repositionis | constituere | 2 | ||

| 13 | Numerus Stationis | non. | 32 | ||

| 14 | Numerus AI | non. | 2 | ||

| 15 | Numerus Axium Moderantium | non. | 5 (X, Y, V, T, C) | ||

| 16 | Typus Instrumentorum | / | Typus Longus | ||

| 17 | Typus Mensae Laboris | / | Infra 3.2mm: Mensa laboris fixa penicillo pleno (Pilae elevatoriae ad onerandum addi possunt ut optio) | ||

| Supra 3.2mm: Mensa laboris plena globorum | |||||

| 18 | Maxima Celeritas Pascendi | Axis X | m/min | 80 | |

| Axis Y | 60 | ||||

| XY Coniuncta | centum | ||||

| 19 | Celeritas Turris | rpm | 30 | ||

| 20 | Celeritas Rotationis Instrumentorum | rpm | 60 | ||

| 21 | Accuratio | mm | ±0.1 | ||

| 22 | Capacitas Oneris Maxima | Kg | 100/150 pro mensa laboris sphaerica | ||

| 23 | Potentia Motoris Principalis | kVA | 45 | ||

| 24 | Modus instrumentorum | / | typus celeris disassemblationis independens | ||

| 25 | Pressio Aeris | MPa | 0.55 | ||

| 26 | Consumptio Aeris | L/min | 250 | ||

| 27 | Capacitas Memoriae CNC | / | 512k | ||

| 28 | Detectio zonae mortuae clampis | / | Y | ||

| 29 | Interruptor contra chartam exuendam | / | Y | ||

| 30 | Interruptor Contra Deformationem Laminae | / | Y | ||

| 31 | Dimensio Adumbrata | mm | 5350×5200×2360 | 5850×5200×2360 | |

| Non. | Nomen | Nota | Gauge | ||

| 1 | Systema CNC | FANUC | OI-PF | ||

| 2 | Servomotor | FANUC | AISV | ||

| 3 | Motor Servo (axis X/Y/C/T) | FANUC | AIS (X, Y, T, C) Motor specialis pro axe V | ||

| 4 | Dux | THK | HSR35A6SSC0+4200L (X:2500) | ||

| HSR35A3SSC1+2060L-Ⅱ (Y:1250) | |||||

| HSR35A3SSC1+2310L-Ⅱ (Y: 1500) | |||||

| 5 | Cochlea globularis | THK | BLK4040-3.6G0+3016LC7 (X:2500) | ||

| BLK3232-7.2ZZ+1735LC7T (Y:1250) | |||||

| BLK3232-7.2ZZ+ 1985LC7T (Y: 1500) | |||||

| 6 | Precisa Gestio | NSK/Koyo | 25TAC62BDFC10PN7B/SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B/SAC3062BDFMGP4Z | |||||

| 7 | Partes pneumaticae | Triarticulatus | SMC | AC30A-03D | |

| Valva solenoidis | SY5120-5D-01 | ||||

| Silentium | AN10-01 | ||||

| Cylindrus | CP96SDB40-80-A93L | ||||

| 8 | Systema Electricum | Interruptor | Schneider | / | |

| Contactus | Schneider | / | |||